Amalgamated Sugar Betaine Separator, Evaporator, and Crystallization Expansion

Nampa, Idaho

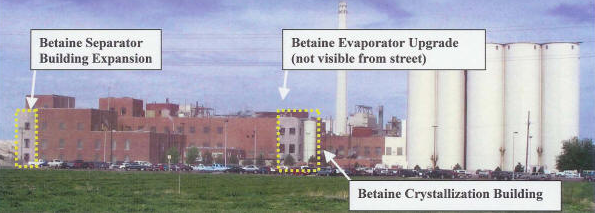

Amalgamated Sugar Company’s largest sugar processing facility added new equipment and structures which enabled the factory to produce another product called betaine. Betaine, a product of sugar beets, is used in the production of some cosmetics. It is also used as a feeding stimulant in ocean fish farming operations. Leavitt Engineering completed the structural design and consulting services for three new building structures related to the project.

The Betaine Separator Building expansion, located at the southwest corner of the existing factory next to Karcher Road, is now home to a new 14-foot diameter by 60-foot high betaine separator and other related equipment. The expansion is a 23-foot wide by 66-foot long single bay addition to the Separator Building previously designed by Leavitt & Associates. The existing steel structure was analyzed using 3D modeling software to ensure that the existing bracing systems were capable of supporting wind and seismic loads required by current building code. Drilled helical anchors were used in the foundation to support the four new steel columns. Exterior walls were constructed of 6-inch thick precast concrete panels with a 4-inch brick face.

Construction began in early 2005 but was halted when the new separator, which was delivered in one piece, encountered a transportation hurdle. Rather than shipping the separator by truck, the separator was eventually transported up the Columbia River to Lewiston, Idaho, making the overland route shorter. Construction resumed after the separator was in place.

The second phase of betaine upgrades was the Betaine Evaporator Upgrade. Not visible from the street, it is located on the north side of the factory. This 13’-6" by 25’-0" four level steel braced frame supports two betaine recovery evaporators and two betaine vapor separators. Like the Separator Building expansion, this structure is an expansion of other work previously designed by Leavitt & Associates. Some existing steel beams were retrofitted to support the new equipment. Only two new spread footings were needed.

Visible from Karcher Road, the final phase of the betaine expansion project, the Betaine Crystallization Building, added about 3,000 square feet of factory floor area near the southeast corner of the factory. Tanks, dryers, conveyors, mixers, elevators, and other equipment in the new Crystallization Building now convert the betaine from liquid to solid form.

The project included a new exterior stair structure, also designed by Leavitt & Associates, and a 15-foot diameter by 60-foot high storage silo, both located immediately east of the new structure. Existing windows in the old factory walls were removed and in-filled with masonry block in compliance with current fire code. The new building has two floors above ground level and one equipment mezzanine.

Contact Info

Address:

1324 First Street South, Nampa, ID 83651

Phone:

(208) 463-0333

Fax: (208) 463-9040

How can we help you?

Call Jimmy Church or Reese Leavitt at

(208) 463-0333 or send an email to:

Jimmy Church: jrc@leavittengineers.com

Reese Leavitt: jrl@leavittengineers.com

Navigation

All Rights Reserved | Leavitt & Associates Engineers, Inc.